When you purchase through links on our site, we may earn an affiliate commission.Heres how it works.

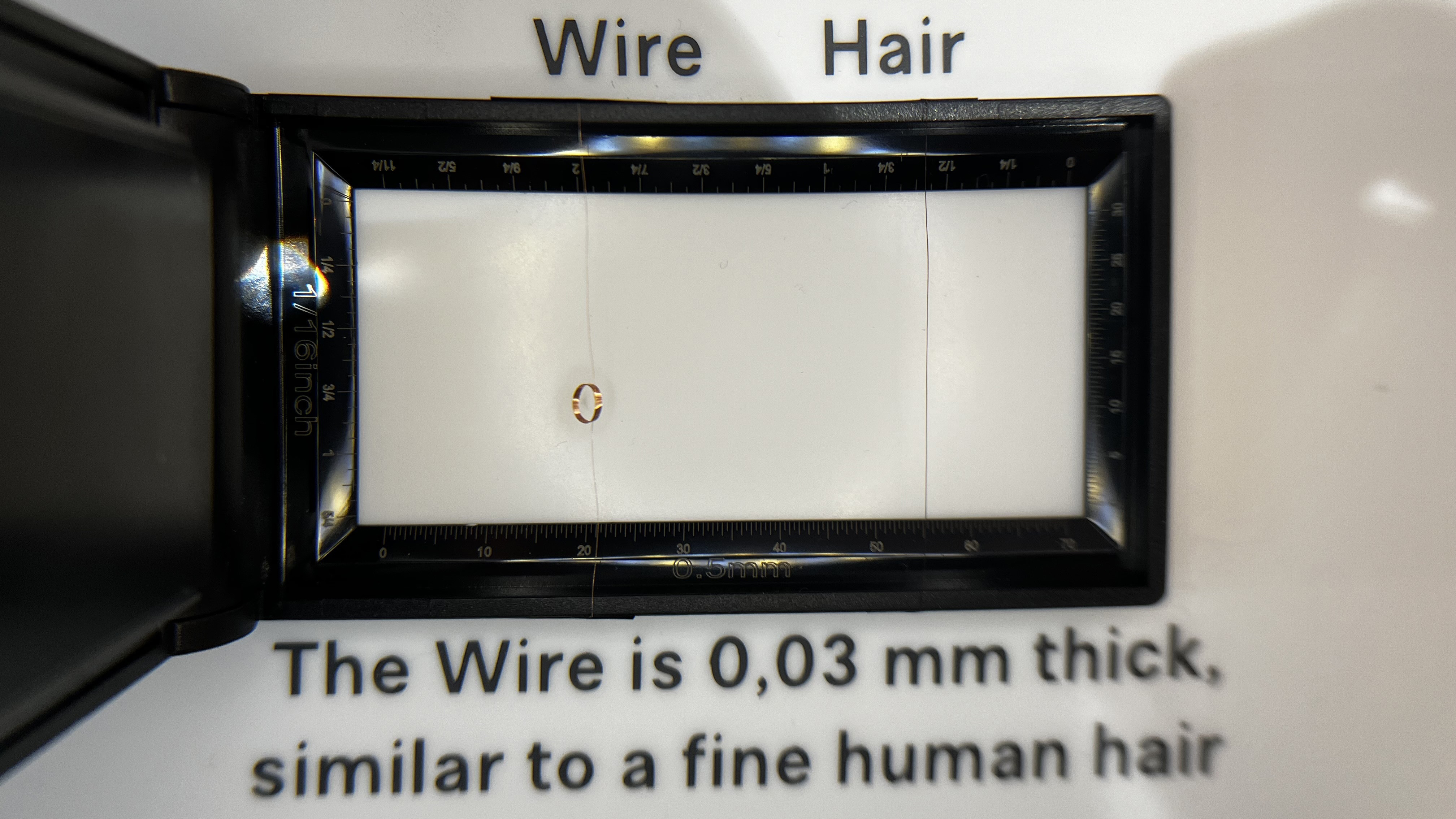

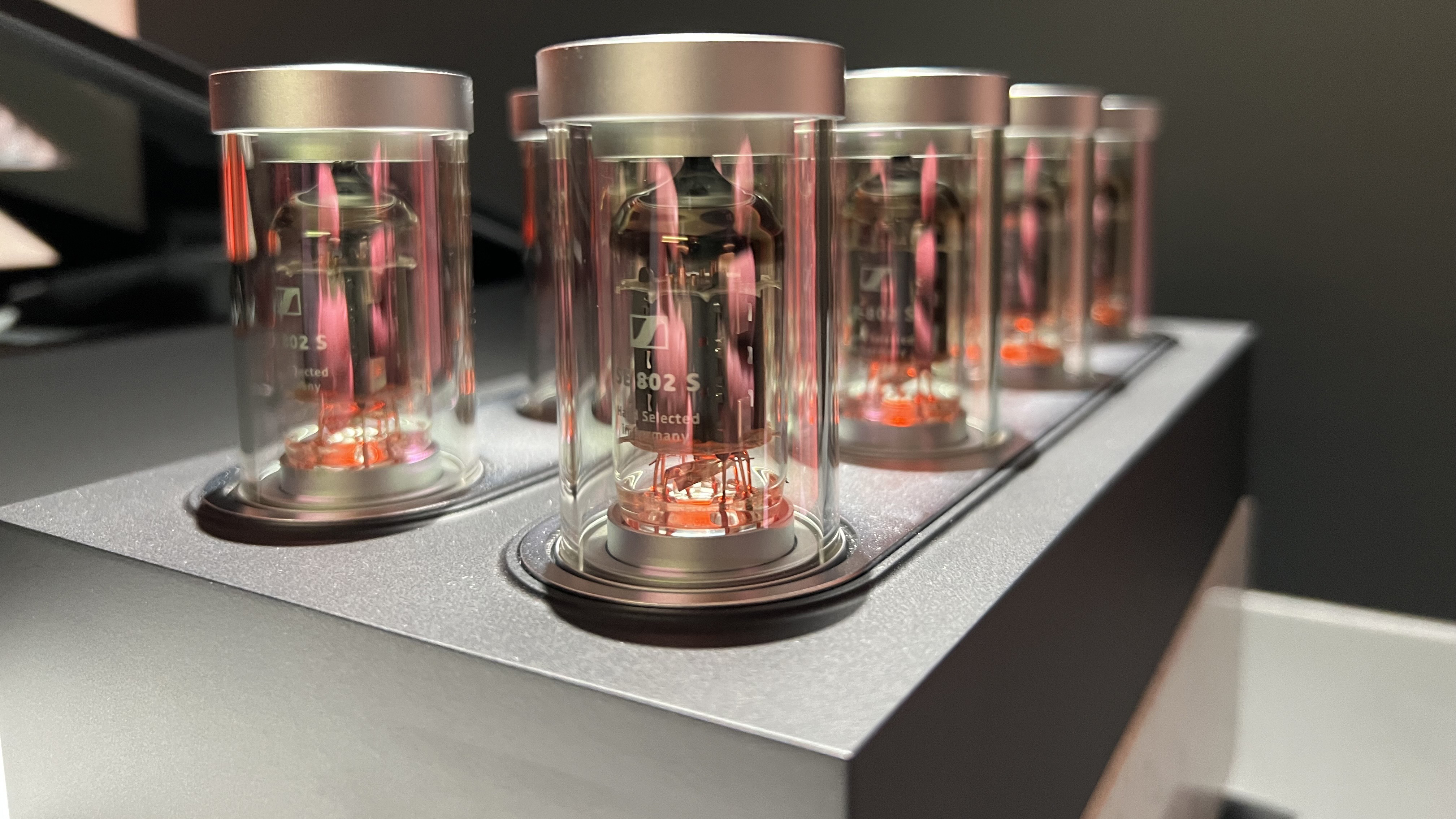

These are what you find inside the earcup, with the speaker driver and the electronics to support it.

It was surreal, and such an impactful demonstration of what goes into this tech.

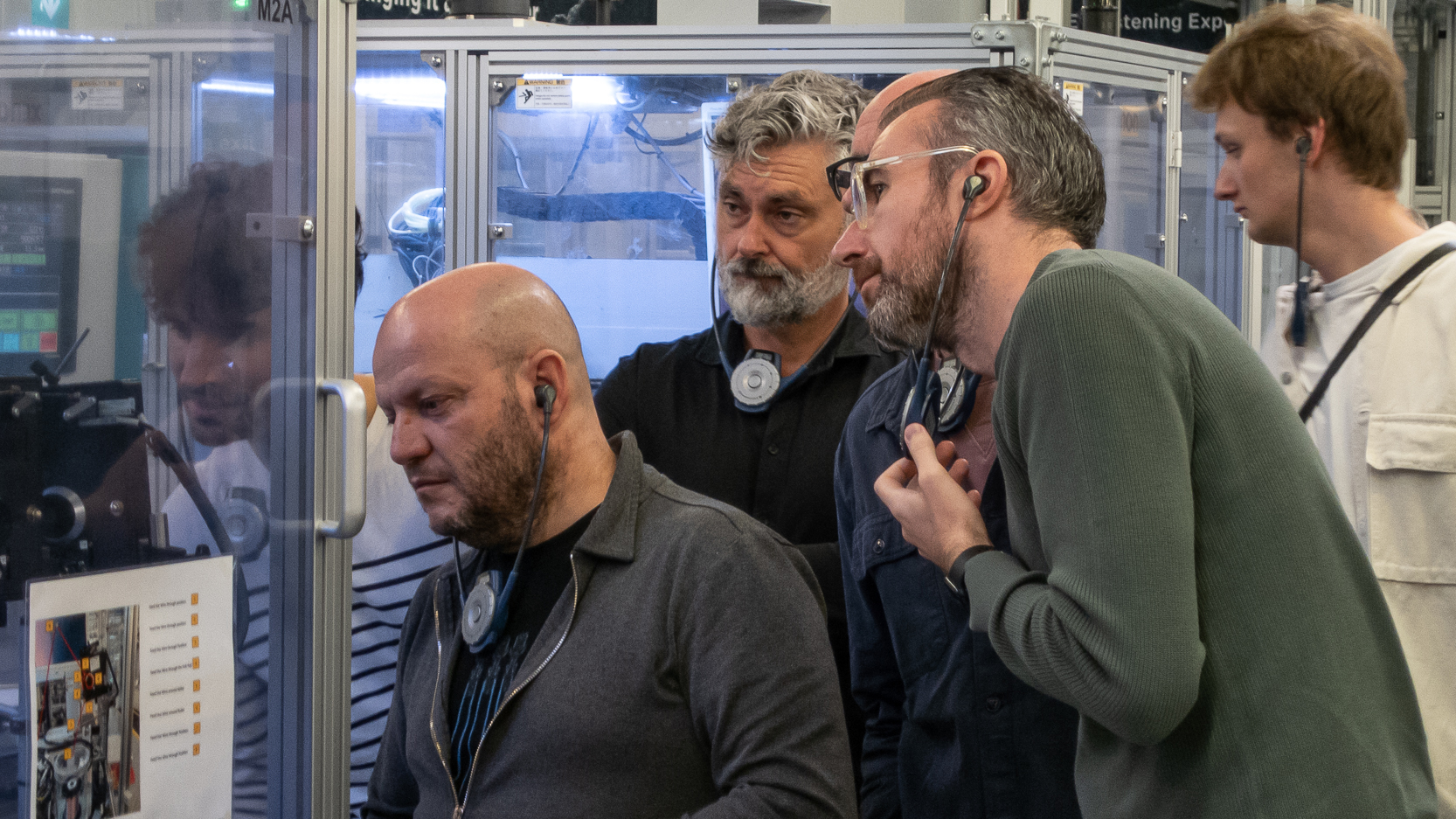

The actual assembly is done in cells, too, to add to the flexibility of the factory.

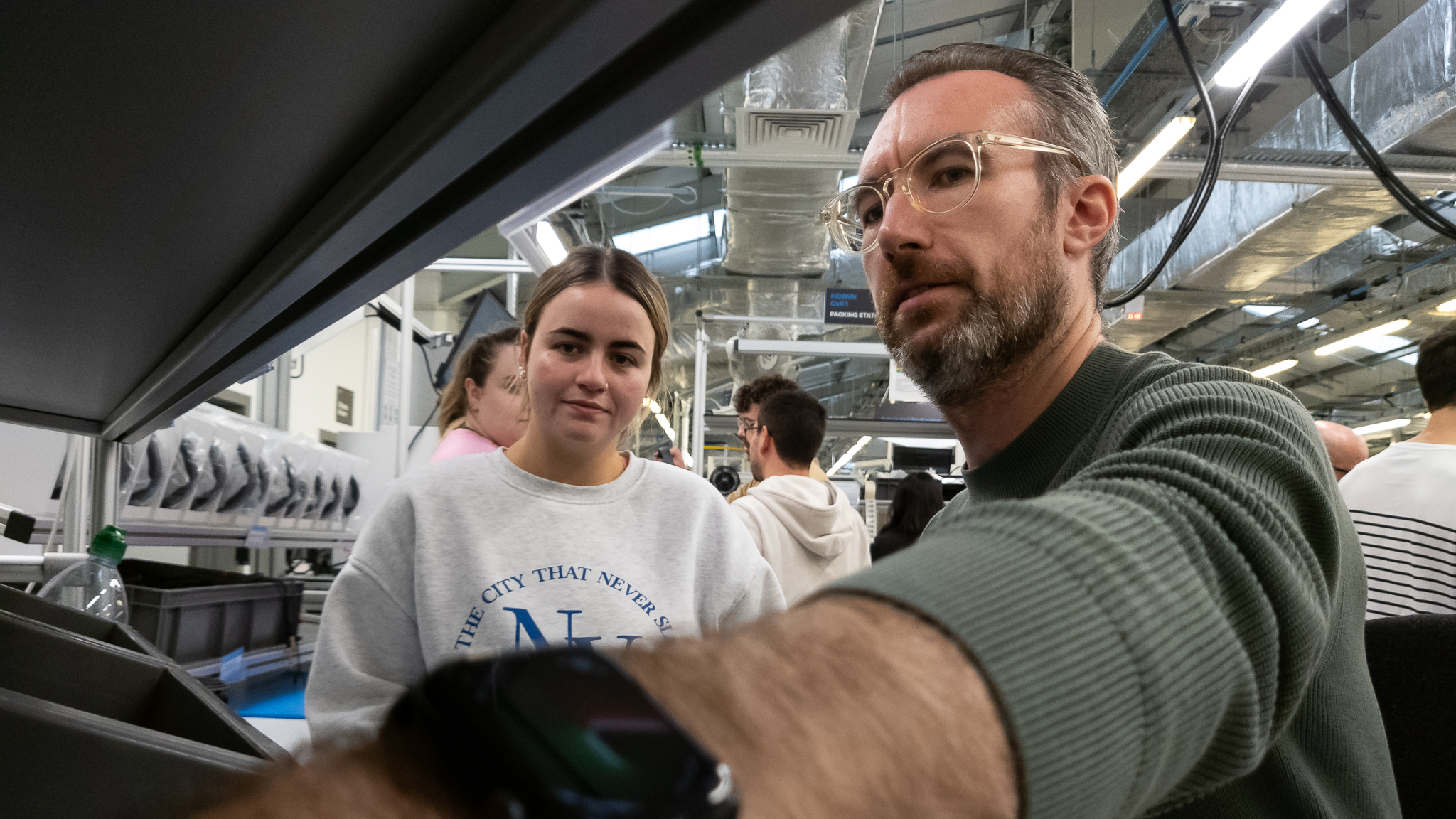

This is where I got to try my hand at building the headphones.

This particular model comes in a few separate parts.

Experience is where it’s at.

These connect on each side of the earcup, and they also need to be inserted with afirmhand.

Next, they went into a booth for final testing.

Amusingly, they go on this stand backwards, so the left earcup is on the right.

One of those technical mysteries we all have in our workplace.

My headphones passed the test first time; perfectly constructed.

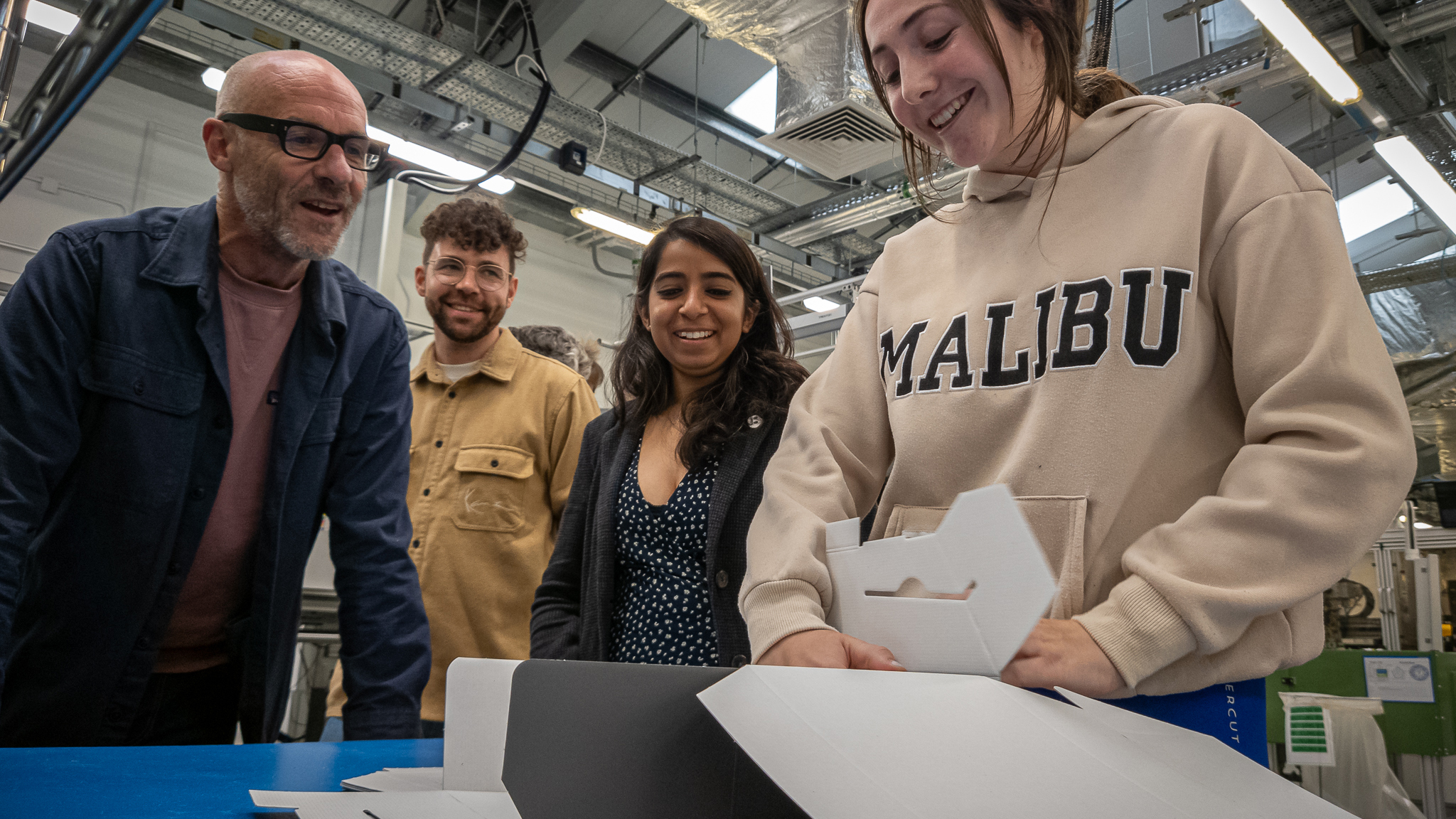

So now we moved on to boxing them up.

Usually, someone has been building boxes for a while, so there’s a stack ready to go.

I needed to make my own box, though, naturally.

This was easily the most daunting part, because this elaborate flat shape isfullof folds.

Separate to all of this is a room at the side of the Tullamore factore.

Only one man works in this section, sealed off from the rest in his own fishtank.

The marble enclosure is not carved here either, funnily enough.

It feels like it’s from the future and the past at the same time.

Did I build this exact pair I’m holding?

Who knows I’ve been telling people I know that I did, because it’s a cooler story.

They’ll be shocked by my white lie if they read this.

That feels pretty cool to me, too.

You might also like